In the world of boat docks, two main options reign supreme: Prefabricated (Prefab) Dock Kits and Custom Builds. Both choices have their merits and drawbacks, with factors like cost, time, customization, and durability playing significant roles in the decision-making process. This comprehensive guide aims to delve into the details, offering you a thorough understanding and assisting you in making an informed decision.

Section 1: Prefab Dock Kits – The Efficient Choice

1.1 Understanding Prefab Dock Kits

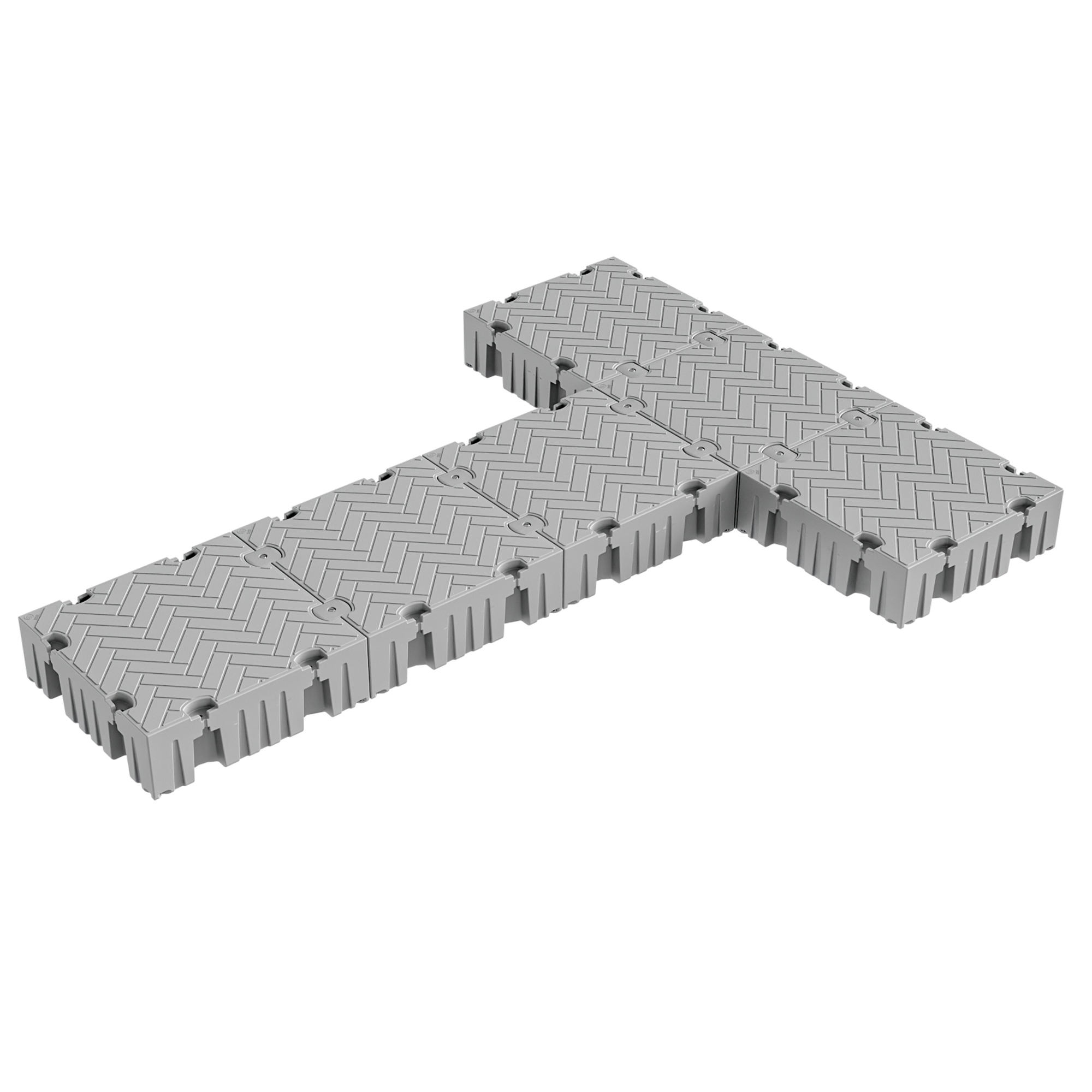

Prefab dock kits, as the name suggests, are pre-manufactured kits that include all necessary parts and instructions to assemble a fully functional boat dock1. They come in a variety of designs, sizes, and materials, offering a range of choices to fit different needs and budgets.

1.2 Material Choices in Prefab Docks

Material selection is a significant aspect of prefab docks, influencing both cost and durability. Common options include treated wood, which is affordable and traditional, but requires more maintenance. Aluminum, a lightweight and durable material, is more costly but can withstand harsher weather conditions. High-Density Polyethylene (HDPE), while the most expensive, provides excellent durability and low maintenance2.

1.3 The Installation Process

Prefab docks come with detailed instructions for assembly, making them a viable DIY project for most homeowners. From laying out the components to securing the dock in place, we will guide you through the process3.

1.4 Maintenance and Lifespan

Like any investment, a dock requires upkeep. While maintenance for prefab docks is typically less intensive, it is crucial to extend the lifespan of your dock. Regular checks for stability, cleaning the surface to prevent slipping, and replacing any worn-out components can ensure the longevity of your investment2.

Section 2: Custom Built Docks – Tailored to Perfection

2.1 The Appeal of Custom-Built Docks

For those seeking a dock as unique as their boat, custom-built docks offer the appeal of personalization. Everything from design, layout, material, and finishing touches can be tailored to the owner's preference.

2.2 Material Selection

The choice of materials significantly influences the dock's appearance, durability, and maintenance requirements. Natural wood is aesthetically pleasing and traditional, but may require regular sealing to prevent water damage. Composite materials, while more expensive, offer superior durability and less maintenance.

2.3 Installation and Building Process

The building process for a custom dock is meticulous and labor-intensive, involving site preparation, design, obtaining permits, and construction. This labor and detail translate into higher costs and a longer timeline compared to prefab docks6.

2.4 Maintenance and Longevity

Maintenance and repair tasks for custom docks will depend on the materials and design used. These may include regular cleaning, resealing (for wooden docks), checking the integrity of the structure, and repairing any damages. However, well-built custom docks, especially those constructed with high-quality materials, can outlive their prefab counterparts5.

Section 3: Market Trends, Environmental Considerations, and Regulations

3.1 Keeping up with Market Trends

The dock industry is evolving, with environmental consciousness playing a more significant role. Both prefab and custom dock manufacturers are incorporating greener solutions, such as using recycled or recyclable materials and minimizing waste during the manufacturing process2.

3.2 Environmental Considerations

Docks interact directly with the water environment. Choosing environmentally friendly materials and designs can minimize the impact on aquatic ecosystems. Also, regular maintenance can prevent parts from breaking off and polluting the water7.

3.3 Local Regulations and Permits

Regardless of whether you opt for a prefab kit or a custom build, compliance with local regulations and homeowner's association rules is critical8. Regulations may dictate dock size, type, location, and even acceptable materials. It's advisable to research these requirements or consult with a local expert before making a decision.

Section 4: Weighing the Options – Prefab vs. Custom Build

4.1 Cost-Benefit Analysis

While prefab docks typically have lower upfront costs, custom builds may offer better value depending on what you find important. If you’re ok with pre-fab dock designs, and you choose one with high-quality materials, then there’s almost no reason why a prefab dock wouldn’t be cheaper. Custom docks are almost always much more expensive.

4.2 Time and Effort

The speed and simplicity of installation for prefab docks contrast with the time and effort required for a custom build. Consider your timeline and the value you place on custom details. For example, if you’re installing the prefab dock yourself, then take into consideration the cost of your time.

4.3 Future Needs and Considerations

Think about the long term – will you upgrade your boat or use the dock for different activities? How might your needs change, and how does each option fit into those future scenarios? A prefab dock may be more versatile in that you can add to it later.

Docking Decisions – Anchoring Your Choice

Choosing between a prefab dock kit and a custom build is a significant decision. Consider all the factors – cost, time, customization, durability, environmental impact, and local regulations. Your perfect dock isn't just about the here and now, but should also navigate the future waters of your evolving boating lifestyle.